基本信息

出生日期:1989/07性别:女

电话:15026578531 E-mail:zhaoman@sues.edu.cn

籍贯:山东省菏泽市 职务:副教授

地址:上海市龙腾路333号4号实训楼4303,201620

学术任职

国外兼任Metals、Micromachining等期刊的客座编委

中国图学学会智能工厂专委会委员

教育经历

国家公派联合培养博士研究生

2015.09-2019.10 东华大学

博士研究生│机械工程│精密加工

2012.09-2015.07 必赢76net线路

硕士学位│机械工程

2008.09-2012.07 临沂大学

学士学位│机械设计制造及其自动化

承担科研及教学项目

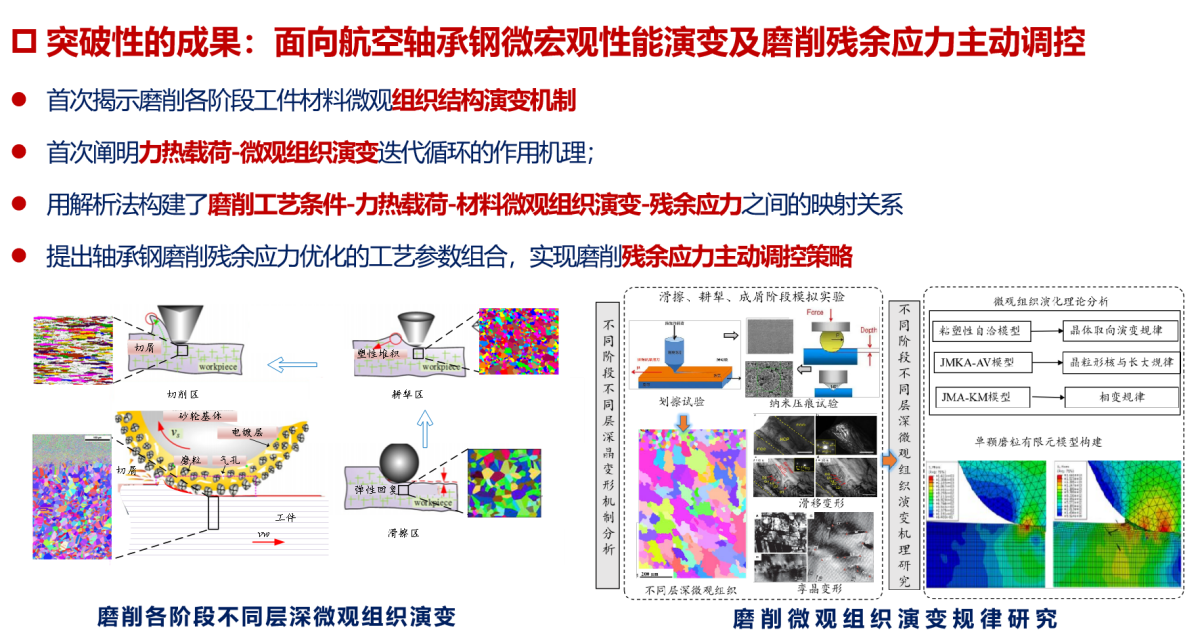

2023 国家自然科学基金NSFC-52205485 │项目主持

【项目名称】轴承钢微观组织演变诱导的磨削残余应力生成机理及预测研究

2020 上海市浦江人才计划 PJ20PJ1404700 │项目主持

【项目名称】基于材料微宏观特性演变的微磨削残余应力生成机理及预测建模研究

2023 必赢76net线路课程建设项目│项目主持

【项目名称】智能制造技术基础

2023必赢76net线路必赢76net线路博士点培育专项重点项目│项目主持

【项目名称】基于实时超声滚压的选区激光熔化残余应力主动调控技术研究

【项目名称】“新工科”与课程思政融合贯通的课程

代表性论著

Zhao, M. (#),Ji, X. , Li, B.Z , & Liang, S. Y. Investigation on the influence of material crystallographic orientation on grinding force in the micro-grinding of single-crystal copper with single grit [J]. International Journal of Advanced Manufacturing Technology. 2017, 90 (9-12):3347-3355 (SCI JCRQ2 IF:2.601)

Zhao, M. (#),Ji, X. , Li, B.Z , & Liang, S. Y. Effect of crystallographic orientation on the hardness of polycrystalline materials AA7075[J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2019, 233(9): 3182–3192 (SCI JCRQ3 IF:1.445)

Zhao, M. (#),Ji, X. & Liang, S. Y. . Influence of AA7075 crystallographic orientation on micro-grinding force [J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2019, 233(8);1831–1843. (SCI JCRQ2 IF:1.982)

Zhao, M. (#),Ji, X. & Liang, S. Y. . Force prediction in micro-grinding maraging steel 3J33b considering the crystallographic orientation and phase transformation [J]. International Journal of Advanced Manufacturing Technology. 2019, 103:2821–2836. https://doi.org/10.1007/s00170-019-03724-z(SCI JCRQ2 IF:2.601)

Zhao, M. (#) ,Ji, X. & Liang, S. Y.. Micro-grinding temperature prediction considering the effect of crystallographic orientation and the strain induced by phase transformation [J]. International journal of precision engineering and manufacturing, 2019, 20: 1861–1876.(SCI JCRQ3 IF:1.661)

Zhao, M.(#) , Ji, X. Feng, Y.X & Liang, S. Y.. Phase transformation prediction considering crystallographic orientation in micro-grinding multi-phase material.Journal of Manufacturing Science and Engineering-ASME. 2020, 142(10): 104501, https://doi.org/10.1115/1.4047492, (SCI JCRQ2 IF:2.875)

Zhao, M., Mao, J. (#), Ji, X. Feng, Y.X & Liang, S. Y.. Effect of crystallographic orientation on residual stress induced in micro-grinding [J]. International Journal of Advanced Manufacturing Technology. https://doi.org/10.1007/s00170-020-06329-z, 2021, 112:1271-1284, (SCI JCRQ2 IF:2.601)

Wang R., Zhao(#) M., Mao J., Liang S. Y. (2022) Force prediction and material removal mechanism analysis of milling sicp/2009al. Micromachines 13 (10): 1687. (SCI JCRQ2 IF:2.891)

Zhu S., Zhao(#) M., Mao J., Liang S. Y. (2022) Study on hot deformation behavior and texture evolution of aluminum alloy 7075 based on visco-plastic self-consistent model. Metals 12 (10): 1648.(SCI JCRQ2 IF:2.695)

Zhu S., Zhao(#) M., Mao J., Liang S. Y. (2022) A ti-6al-4v milling force prediction model based on the taylor factor model and microstructure evolution of the milling surface. Micromachines 13 (10): 1618.

Mao J, Zhao, M., An approach for the evaluation of sphericity error and its uncertainty, Advances in Mechanical Engineering, 2013:1-5

Wang J, Ye Q, Zhao M, Shi X, Fei T. Multi-objective parametric optimization for high surface quality and process efficiency in micro-grinding. Measurement and Control. 2021;54(5-6):916-923.

Liu H., Zhao M., Zhou Y., Liu G. (2021) Research on modeling crystallographic texture evolution of al alloy 7075. Frontiers in Materials 8. 10.3389/fmats.2021.773501

2. 第一作者EI期刊论文

Zhao, M. (#),Ji, X. , Li, B.Z , & Liang, S. Y. Forces prediction in micro-grinding single-crystal copper considering the crystallographic orientation[J]. Manufacturing Review. 2018, 5(15):1884-2020

Zhao, M. (#) , Ji, X. & Liang, S. Y. . Micro-grinding temperature prediction considering the effects of crystallographic orientation [J]. Manufacturing Review, 2019,6(22): 1-11.

3、中文期刊

赵嫚(#),王荣,茅健,张立强.马氏体合金钢3J33b磨削力热载荷-晶粒尺寸演变的动态迭代作用机制研究[J].表面技术,2023,52(07):217-230.

茅健,赵嫚(#),张立强. 晶粒取向对微细加工磨削力作用机理及实验研究[J]. 机械工程学报2021,57(5):262-272.

赵嫚(#),茅健.面向制造过程的装配公差建模研究[J].工程设计学报,2014, 21(6):529-533.

栾振猛,赵嫚(#),茅健,张立强,刘钢. 超声振动对退火态Cr4Mo4V轴承钢拉伸性能影响的试验研究[J].轴承,2024,1-7.

张志慧,赵嫚(#),王荣,朱思远,茅健,张立强TC4磨削表面晶粒取向演变及微观形貌实验研究[J].航空制造技术,2024,1-7.

王荣,赵嫚(#),赵克光,等.基于材料静动态力学性能分析的SiCp/Al本构模型构建[J].功能材料,2024,55(02):2215-2223.

4、已发表的国际会议论文及其他

Zhao, M, J. Mao. The study of assembly tolerance relational diagram based on the assembly hierarchical model. Procedia CIRP 56 ( 2016 ) 220-22 (EI 收录)

Mao J, Zhao, M, Mathematical model for assembly tolerance consistence evaluation, Applied Mechanics and Materials, 2013, 401-403: 1610-1613 (EI收录).

专利及软著

一种基于航空零部件表面孔隙缺陷用打磨修复装置中国ZL202310671515.32023/6/8刘钢;赵嫚

一种用于航天航空薄壁曲面部件的焊接装置及其方法中国CN202310692032.12023/6/13刘钢;赵嫚

代表性科研成果